Research & Development

Posted on

October 17, 2021

in

Advancement In Torsional Damper

New Trends in Automotive Engines

- Emission regulation compliance.

- Reduction in fuel consumption and CO2 emissions.

- EGR

- After treatment systems.

- Engine downsizing

- More power from smaller engines.

- Flat torque curve for almost 70% of engine speed.

- Cylinder cutoff or deactivation.

- Cylinder fuel cut off at partial load or idle condition.

- Reducing number of cylinders.

- Engine over speeding conditions.

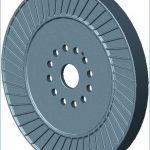

- Low Density

- Better heat transfer coefficient than casting

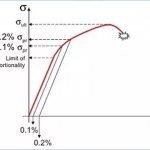

- Mechanical properties at par with S.G. Iron

- Reduction in wastage in the manufacturing process

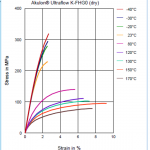

Advance Material

- High Heat stability upto 200°C.

- Higher tear resistance.

- Excellent resistance to oil, coolant, fuels and hydrocarbons.

- Better damping properties.

- High elasticity.

- Lower compression set.

Advance Material 1

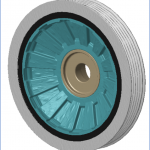

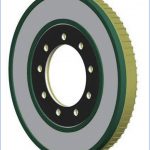

Fin Design

- Fins are passive heat exchangers.

- Better convective heat transfer coefficient.

- Better conductive heat transfer coefficient.

- Higher under hood and operating temperatures.

- Airflow direction.

- As cast fins on damper housing.

Advance Damping Material

- Change in viscosity is lower at higher shear rate.

- High Heat stability upto 140°C.

- High Shear Stability.

- Retaining damper functionality over lifetime.

- Rapid change in rheological characteristics.

- High damping can be achieved in lower envelope size

- High heat stability

- Limitations