Research & Development

Posted on

October 17, 2021

in

Prototype Testing

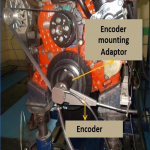

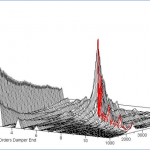

Natural Frequency Test

- Servo Hydraulic Vibratory Damper Test System

- Precision system with controlled rotary actuator through servo hydraulic system.

- Damper Hub is mounted on rotary actuator and represents the actual mounting condition.

- Rotary actuator is excited through a servo value with known excitations.

- Two accelerometers are mounted in phase, one on actuator and the other on Damper inertia ring. Which in turn acts as closed loop circuit.

- The excitations exerted by the actuator are captured by the accelerometers.

- As the ring is separated through elastomeric member there is a difference in phase between the excitations of two sensors.

- At resonance the difference in phase is exactly 90 deg. Which determines the Natural frequency of the damper.

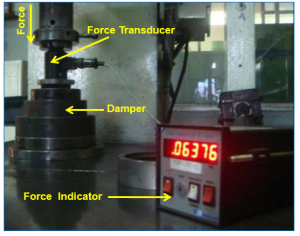

Axial Pull Test

- Damper is mounted onto the fixture.

- A force transducer is placed onto the damper.

- A precisely controlled press is used to find out the axial force & the adhesive strength of the damper.

- An indicator is connected to transducer and the maximum value is displayed.

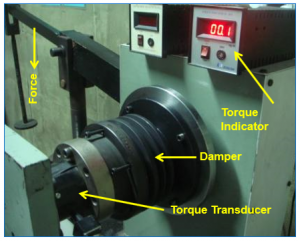

Slip Torque Test

- Torque applied under static condition on the damper elastic member by fixing either inertia ring or hub & gradually displacing the other to measure the Torsional bonding strength of the rubber element under assembly.

- Damper Hub is mounted onto torque lever.

- Damper Ring is fixed onto the torque transducer.

- Torque is applied gradually onto the damper hub.

- The amount of torque exerted is indicated by an indicator.

- Sudden drop in the torque reading indicates slip between hub & ring.

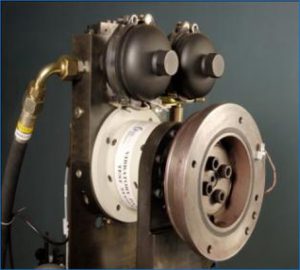

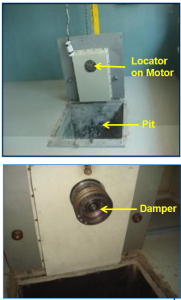

Burst Testing

- Damper is mounted onto locator through a motor.

- Damper is run at 2.5 times the rated RPM of engine for 2 minutes.

- Test is carried out to find out the structural integrity of the cast part and bond integrity of elastomer and the metal parts.

- Shift in correlation mark is checked before and after test.

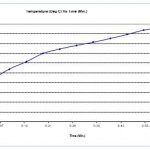

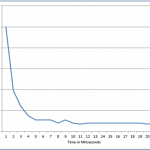

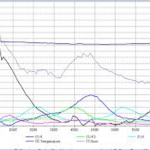

Hooke’s Joint Test

- Viscous damper is excited on Hooke’s joint with angular excitation.

- Temperature rise of the damper casing is measured.

- Temperature rise should be linearly or gradual rise with respect to time.

| Hooke’s Angle | Angular Displacement |

| 10 ° | 0.438 ° |

| 11 ° | 0.531 ° |

| 12 ° | 0.633 ° |

| 13 ° | 0.744 ° |

| 14 ° | 0.864 ° |

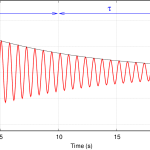

Torsio Test Rig

- Damper mounted on rig and excited manually.

- Decay in the amplitude level of the given excitation is monitored.

- If decay in amplitude level observed, damper is functionally acceptable.

- If damper ring is seized no decay in amplitude level is observed.